| Be-Cu Alloy |

Alloy Be-Cu Alloy

Name |

Electrical Resistivity -

at 20°C(μΩ.Cm) |

TCR -

(TC in ppm/K) |

TCR -

(between) |

Density -

(g/cm3) |

Din Material -

Code |

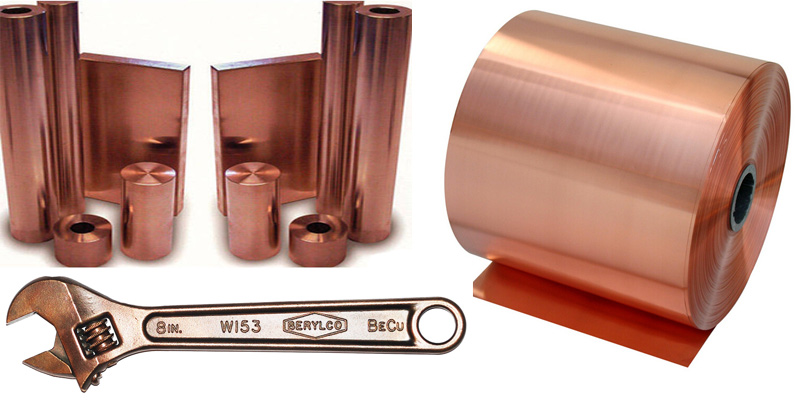

Be-Cu Alloy Functions

Beryllium copper is a ductile, weldable, and machinable alloy. It is resistant to non-oxidizing acids (for example, hydrochloric acid, or carbonic acid), to plastic decomposition products, to abrasive wear, and to galling. It can be heat-treated for increased strength, durability, and electrical conductivity. Beryllium copper attains the greatest strength (to 1,400 MPa (200,000 psi)) of any copper-based alloy.[1] It has good thermal conductivity (62 Btu/ft-deg.F-H) 3-5 times more than Tool steel.

Beryllium copper is a non-ferrous alloy used in springs, spring wire, load cells, and other parts that must retain their shape under repeated stress and strain. It has high electrical conductivity, and is used in low-current contacts for batteries and electrical connectors

Beryllium copper is non-sparking but physically tough and nonmagnetic, fulfilling the requirements of ATEX directive for Zones 0, 1, and 2. Beryllium copper screwdrivers, pliers, wrenches, cold chisels, knives, and hammers are available for environments with explosive hazards, such as oil rigs, coal mines, and grain elevators. An alternative metal sometimes used for non-sparking tools is aluminium bronze. Compared to steel tools, beryllium copper tools are more expensive, not as strong, and less durable, but the properties of beryllium copper in hazardous environments may outweigh the disadvantages. Some other uses include:

Beryllium copper wire is produced in many forms: round, square, flat and shaped, in coils, on spools and in straight lengths.

Beryllium copper valve seats and guides are used in high performance four-stroke engines with coated titanium valves. BeCu dissipates heat from the valve as much as seven times faster than powdered steel or iron seats & guides. The softer BeCu reduces valve wear and increases valve life.[

Beryllium copper (C17200 & C17300) is an age-hardening alloy which attains the highest strength of any copper base alloy. It may be age hardened after forming into springs, intricate forms or complex shapes. It is valued for spring properties, corrosion resistance, stability, conductivity, and low creep.

Tempered beryllium copper is C17200 & C17300 that has been age hardened and cold drawn. No further heat treatment is necessary beyond a possible light stress relief. It is sufficiently ductile to wind on its own diameter and can be formed into springs and most shapes. Tempered wire is most useful where the properties of beryllium copper are desired, but age hardening of finished parts is not practical.

C17510 and C17500 beryllium copper alloys are age-hardenable and provide good electrical conductivity, physical properties, and endurance. They are used in springs and wire where electrical conduction or retention of properties at elevated temperatures is important.

Be- Cu alloy Application

1.The high-performance beryllium copper mainly surrounds various working conditions of low-pressure and gravity casting molds for non-ferrous metals.

2.The high-performance beryllium bronze mold material combining strength, wear resistance, high temperature resistance, high toughness and metal liquid corrosion resistance solves the problems of low pressure of non-ferrous metals, cracking of gravity casting molds, easy wear and the like, and significantly improves the life of the mold.

3.Demolition speed and casting strength; overcome metal slag adhesion and erosion of the mold; improve the surface quality of the casting; reduce the production cost; make the mold life close to the import level.

4.High-performance beryllium copper hardness HRC43, density 8.3g/cm3, containing Be 1.9%-2.15%, it is widely used in plastic injection molding molds for inserts, cores, die-casting punches, hot runner cooling systems, thermal nozzles, blowing The overall cavity of the mold, automobile mold, wear plate, etc.

NEXTECK supplies variety standards and customized world-class resistance alloys. All materials from strips, sheets, foils, wires as well as E-Beam Welding strips (EBW) are built for low value surface mount resistors, auto potentiometers, consumer electronics, tests, automatic controls and other fields.

NEXTECK originated in the metal smelting and processing and has a very long history. We belongs to the world's leading company in the production of thermo-electric alloys, resistance alloys, low resistance precision resistances and power resistances.

It is more effective to ensure product quality and customer service. Our measurements (standard temperature, mechanical and electronic) received long-term monitoring, which ensures the accuracy of the product again. The chemical and physical properties of our alloys are ensured through modern measuring and analysis systems. Among others, these include: optical emission spectrometer, surface electron microscope (SEM), EDX analyzer, elongation tester as well as length and hardness test devices.

| ALLOY NAME | DIN SYMBOL | R.VALUE | CONDUCTIVITY | TCR ON PPM/K | TEMP RANGE | DENSITY | DIN CODE |

| μΩ/Cm/20°C | S/W | g/cm3 | |||||

| NEXTMFCA145 | FeCr21Al6 | 145 | - | +33 | 20 and 100°C | 7.10 | - |

| NEXTMFCA142 | FeCr21Al4 | 142 | - | +40 to +60 | 20 and 100°C | 7.9 | - |

| NEXOHM® | NiCr20AlSi | 132 | 0.76 | Standard:±50. Special:±3. ±10°C | 20 and 105°C | 8 | 2.4872 |

| NEXTMNC6015 | NiCr6015 | 111 | 0.9 | +100 to +200 | 20 and 105°C | 8.2 | 2.4867 |

| NEXTMNC8020 | NiCr8020 | 108 | 0.93 | +50 to +150 | 20 and 105°C | 8.3 | 2.4869 |

| NEXTMNC3020 | NiCr3020 | 104 | 0.96 | +300 to +400 | 20 and 105°C | 7.9 | 1.486 |

| NEXTMCM25 | CuMnNi25-10 | 90 | 1.11 | ±10 | 20 and 50°C | 8 | - |

| NEXCN44® | CuNi44 | 49 | 2.04 | Standard:-80 to +40 Special:±10 | 20 and 105°C | 8.9 | 2.0842 |

| NEXTMNC30F | NiCu30Fe | 49 | 2.04 | +400 to +600 | 20 and 105°C | 8.9 | 2.436 |

| NEXMANGAN® | CuMn12Ni | 43 | 2.33 | Standard:±10 Special:±3 | 20 and 50°C | 8.4 | 2.1362 |

| NEXTMCN30M | CuNi30Mn | 40 | 2.5 | +80 to +130 | 20 and 105°C | 8.8 | 2.089 |

| NEXTMNF30 | NiFe30 | 33 | 3.03 | Approx +3200 | 0 and 100°C | 8.5 | - |

| NEXTMCN23M | CuNi23Mn | 30 | 3.33 | Approx +180 | 20 and 105°C | 8.9 | 2.0881 |

| NEXZERAN® | CuMn7Sn | 29 | 3.45 | Standard:±10. Special:±3 | 20 and 60°C | 8.5 | - |

| NEXTMNF28 | NiFe28 | 21 | 4.76 | Approx +4500 | 20 and 100°C | 8.5 | - |

| NEXTMCN15 | CuNi15 | 21 | 4.76 | Approx +300 | 20 and 60°C | 8.9 | - |

| NEXTMCN10 | CuNi10 | 15 | 6.67 | +350 to +450 | 20 and 105°C | 8.9 | 2.0811 |

| NEXTMCM3 | CuMn3 | 12.5 | 8 | +280 to +380 | 20 and 105°C | 8.8 | 2.1356 |

| NEXTMCN6 | CuNi6 | 10 | 10 | +500 to +900 | 20 and 105°C | 8.9 | 2.0807 |

| NEXTMN99.2 | Ni99.2 | 9 | 11.1 | +4700 to +5800 | 0 and 100°C | 8.9 | 2.4066 |

| NEXTMN99.6 | Ni99.6 | 8 | 12.5 | +5300 to +6400 | 0 and 100°C | 8.9 | 2.406 |

| NEXTMN99.4 | Ni99.4Fe | 8 | 12.5 | 6180 | 0 and 100°C | 8.9 | 2.4062 |

| NEXTMN99.98 | Ni99.98 | 7 | 14.3 | 6600 | 0 and 100°C | 8.9 | - |

| NEXTMCN2 | CuNi2 | 5 | 19.8 | +1000 to +1600 | 20 and 105°C | 8.9 | 2.0802 |

| NEXTMCN1 | CuNi1 | 2.5 | 40 | 3000 | 20 and 105°C | 8.9 | - |

| NEXTMCC0.3 | CuCr0.3 | 1.92 | - | 3000 | 20 and 105°C | 8.9 | - |

| NEXTMC99.9 | Cu-ETP/(E-Cu57) | 1.7 | 58.8 | 4300 | 0 and 100°C | 8.9 | 2.006 |

| NEXTMCT3/CTF0.2 | 86 | 20 | 18.6 | - | 8.7 | - | |

| NEXTMCF | CuFe | 132~172 | 10~13 | 18 | - | 8.7 | - |

NEXTECK (CHINA) - SHENZHEN

Tower A1001, Galaxy Century, No 3069, CaiTian Rd, Futian District, Shenzhen, China

Zip Code: 518026

Tel: +86-755-8256-1631

Fax:+86-755-8256-1691

E-mail:nexteck@nexteck.com

Hotline:+86-400 882 8982

PRODUCTION PLANT

Wenchuan Rd, Alley 5300/1, Baoshan District, Shanghai, China

Zip Code: 200942

Tel: +86-21-3638-0189

Fax: +86-21-3638-0109

E-mail: nexteck@nexteck.com.cn