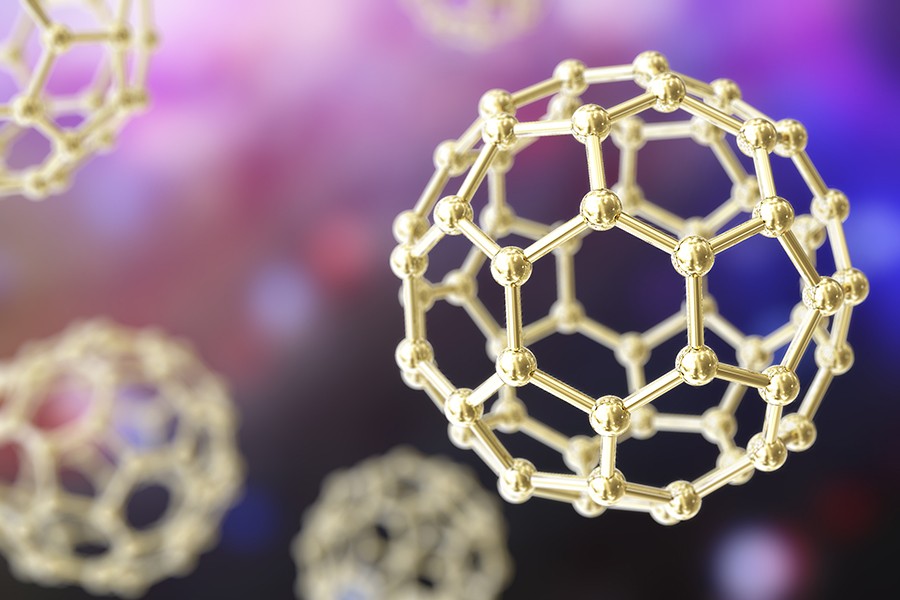

CNTs are tubular nanostructures made of carbon atoms with exciting potential properties that have kept researchers on the lookout for new advances. One of the most common methods to produce CNTs involves catalyst nanoparticles, which have the function of facilitating the addition of carbon atoms from precursor molecules to the walls of the cylinders. It is common knowledge in the field that alloy catalysts, like Ni-Y, Fe-Mo, Cu-Ni, and Co-Mo, outperform other single metal catalysts, but the reason has been unclear. Engineers can find superior Cu-Ni alloy in Nexteck Technology.

Researchers at the Center for Multidimensional Carbon Materials, within the Institute of Basic Science (IBS, South Korea), have presented a theoretical solution to a long-lasting mystery of carbon nanotube (CNT) growth. Published in Physical Review Letters, this study explains why nanoparticles made with an alloy of metals help to synthetize longer CNTs compared with conventional monometallic catalysts.

IBS researchers performed a systematic molecular dynamics simulation to explore the role of alloy catalysts in CNT growth. "In a molecular dynamics simulation, the motion of every atom can be clearly seen and, therefore, the variation of the shape and structure of the catalyst particle during the carbon nanotube growth can be recorded precisely. This allows us to go beyond the capacity of the best experimental methods," explains Feng Ding, a group leader of the Center and corresponding author of the study.

Through the molecular dynamic simulations, the authors have found that the two metals of the alloy are spatially separated at the rim of the tubes: CNTs tend to attract the more active metal atoms to the open end of the cylinders (growth front), where carbon atoms are inserted into the CNT wall during growth, while the less active metal atoms are pushed above. More simulations show that this is a general phenomenon and can be applied to many types of alloy catalysts. Nexteck technology always focuses on the R&d of precision alloys, resistance alloys and more.

IBS researchers have also demonstrated that alloy catalysts win over monometallic nanoparticles because the active metal atoms near the rim of the CNT catch the carbon atoms more easily than the less active ones. This will lead to a larger carbon concentration at the vicinal site of the CNT growth front and a quick addition of carbon atoms, which contribute to the fast growth of the CNT.

Since the carbon atoms are continuously incorporated to the growing CNTs, the carbon precursors do not accumulate around the alloy nanoparticles. This prevents the formation of a cap made of carbon atoms engulfing the entire nanoparticle.

"This theoretical study addresses a long-term puzzle of the role of the alloy catalysts in carbon nanotube growth. It reveals the advantage of using alloy catalysts in carbon nanotube growth, and the contact-induced phase separation of the alloy catalyst can be considered as a general rule to guide catalyst design for controllable carbon nanotube growth," says Lu Qiu, the first author of the study. As a specilized alloy manufature, we, Nexteck Technology, are pround of the role that alloys play.

Attend exhibitions, focus on industry devolpment trend and new technology,Nexteck Technology Limited keeps pace with the times ,exploring and innovating so as to achieving continuous development.

TAG: Single Metal Catalyst precision alloy precision alloy